Welcome to your expert for sheet metal processing! Our company combines state-of-the-art technologies with years of experience to offer you first-class solutions for your individual requirements. We specialise in processing a wide range of materials such as sheet steel, stainless steel, aluminium and non-ferrous metals and offer you a broad spectrum of services such as CNC bending, laser cutting, laser welding, spot welding and surface finishing. Our aim is to guarantee you the highest quality, precision and efficiency in all our projects. Discover our wide range of services and let our professional team help you realise your projects.

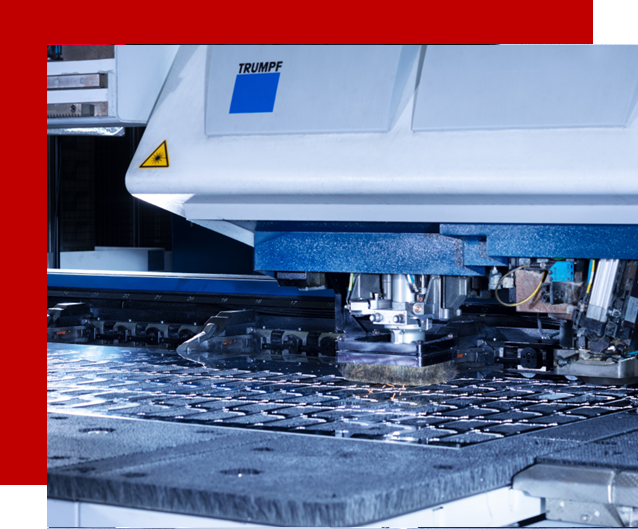

Our automated laser punching center ensures maximum throughput. Processing continues immediately: the raw material high-bay warehouse, the sheetmaster for loading and unloading, and tool storage are directly connected to the equipment.

We machine the following materials:

Benefit from the advantages of our laser punching centres: Combination technologies, new punching methods and the associated process and part optimisation ensure high efficiency, minimised material consumption and low costs. The operation runs in three shifts - one of which is completely automatic.

HAKAMA relies on CNC bending technology and experienced specialists to achieve perfect results when processing sheet steel, stainless steel and aluminium. Our efficient processes enable fast and precise production, even for small batch sizes. Trust in HAKAMA quality and benefit from state-of-the-art technologies.

First-class quality without additional material or subsequent plastering

Thanks to the advanced laser welding technology at HAKAMA, you benefit from efficient manufacturing processes and the highest quality. Our experienced skilled workers or precise robots use concentrated heat guidance and minimise distortion, making time-consuming reworking mostly unnecessary. Our high-precision fine welding processes produce virtually stress-free and discolouration-free results.

Materials to be processed:

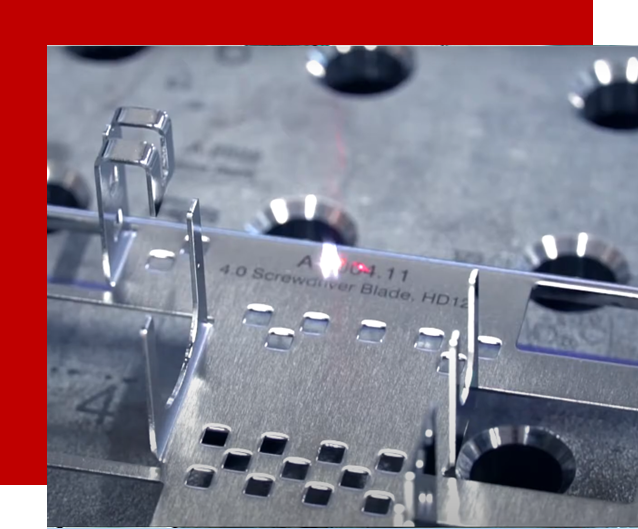

Precise, durable and abrasion-resistant - the ideal marking process for demanding applications

Our ultra-short pulse laser offers innovative solutions for perfect laser markings on metals in medical technology and other industries. With the unique PERMAblack process, we achieve rich black markings that are visible regardless of the viewing angle.

Invisible connections for convincing stability and appealing appearance, executed by experienced experts

Our team of trained experts at HAKAMA is a master of spot welding and ensures invisible, extremely stable and durable connections. By combining many years of know-how and high-quality materials, we achieve a result that is visually convincing, guarantees absolute strength and is easy on your budget. And, of course, quickly and efficiently - just as our customers expect from us.

HAKAMA offers impressive surface finishes through a variety of processes realised in cooperation with a network of specialised suppliers. Our experts offer solutions for different requirements, from surface coating to engraving and screen printing.

Surface coatings:

Laser inscription:

Engraving:

Silkscreen:

| Material | Designation / Recommendation | Short name according to EN | DIN EN / ASTM-Nr. |

|---|---|---|---|

|

ST 1.4016 |

Stainless steel sheet, moderately weldable, additional heat treatment is recommended, medium corrosion resistance, magnetic = good EMC shielding |

X 6 Cr 17 |

EN 10 088-2 ASTM 430 |

| ST 1.4301 | Stainless steel sheet, very good weldability/deep drawability, good corrosion resistance. Use:Household goods, construction industry, water, food industry. | X 5 CrNi 18-10 | ASTM 304 |

| ST 1.4404 | Stainless steel sheet, very good weldability/deep-drawability, very good corrosion resistance. Application: in apparatus engineering, in the chemical and pharmaceutical industry. |

X 2 CrNiMo 17-12-2 | EN 10 088-2 ASTM 316 L |

| ST 1.4571 | Very good weldability, very good corrosion resistance. Applications: Chemical industry, implants, construction industry. |

| Material | Designation / Recommendation | DIN EN-Nr. | Material Nr. |

|---|---|---|---|

| AI 99.5% | Pure aluminium 99.5%, Normal quality, conditionally suitable for decorative anodic oxidation, Tensile strength N/mm2 110-150 | EN AW-1050 | 3.0255.27 |

| AIMg 1 | Peraluman 101 colourless anodisable, well suited for decorative anodic oxidation, Tensile strength N/mm2 145-185 | EN AW-5005 | 3.3315.27 |

| AIMg 3 | Peraluman 301, colourless anodisable, well suited for decorative anodic oxidation, tensile strength N/mm2 240-280 | EN-AW-5754 | 3.3535.27 |

| Alunox | Peraluman, surface resistant, no fingerprints, high-tech look, even surface, lightweight, one third the weight of stainless steel. Surface: Butler finish on both sides. Anodisation 5 my according to EN 12373 on good side not weldable, no spot welding Use: Household appliances, coffee machines, kitchen furniture, hygiene, medicine. | EN-AW-5005 | 3.331 |

| Material | Designation / Recommendation | DIN EN-Nr. | Material- and DIN-Nr. |

|---|---|---|---|

ST 12.03 DC 01 | Decapitated thin sheets, fine-flat cold-rolled, with matt/lightly oiled surface Suitable for laser cutting, laser, inert gas and resistance welding as well as phosphating and painting. Grade for cold forming, bending, profiling, folding, stamping and pressing | EN 10130 | 1.0330 |

ST 14.03 DC 03 | Caped deep-drawn sheets cold-rolled, with matt/lightly oiled surface Suitable for laser cutting, laser, inert gas and resistance welding as well as for phosphating and lacquering. Grade for cold forming, bending, profiling, folding, stamping and pressing. | EN 10130 | 1.0338 1623-T1 1624 |

| ST 02 Z | Sendzimir galvanised sheet, cold rolled Coating on both sides: chromated Zinc coating 275 g/m2 Use: Wall and roof | EN 10 142 | 1.0226 17162-T1 |

| ST 12 ZE | Zincor, cold-rolled sheet, electrolytically galvanised Coating on both sides: chromated and phosphated, zinc coating 36g/m2 Use: electrical industry, steel furniture, agriculture | EN 10 152 DC01 + ZE | 1.033 17163 |

| AZ 150 | Aluzinc, cold-rolled steel sheet with 0.25µ coating / side Support layer of cold-rolled quality sheet continuously coated with an aluminium-zinc alloy in a hot-dip process: 55.0% aluminium 43.4% zinc 1.6% silicon Use: not recommended Machining techniques: welding and spot welding Ideally suited for mechanical joints such as riveting, toxing / joining |

Simply fill out the contact form with your request and we will usually get back to you within 2 working days at the latest.

Mit dem neuen Ultrakurzpulslaser eröffnen sich Ihnen, gerade in der Medizintechnik neue interessante Möglichkeiten der perfekten Lasermarkierung auf Metallen aller Art, die wir auf unseren neuesten Feinblechlösungen für Geräte namhafter Hersteller mit hervorragenden Vorteilen anbringen:

für fast jedes Material

auch auf lackierten Oberflächen

extrem resistent gegen abrasive, chemische und Strahlenbelastung

Gleicher Kontrast bei allen Lichteinfalls- und Betrachtungswinkeln

Idealer Ersatz für Siebdruck

Consecutive serial numbers possible

präzise und schnell

Eine satte Schwärzung der Oberfläche von Metallen erreicht man durch die Verwendung des Ultrakurzpulslasers, dem einzigartigem PERMAblack -Verfahren oder auch Dunkelmarkierung. Die mit diesem Laser erzeugten Markierungen und Beschriftungen erscheinen tief schwarz und das, im Gegensatz zu Anlassfarben, unabhängig vom Betrachtungswinkel. Werden korrosionsbeständige Teile mit dem Ultrakurzpuls Laser schwarz markiert, sog. Black Marking, ist eine anschließende Passivierung (Schutz vor Korrosion) der markierten Fläche, im Gegensatz zu einer Laserbeschriftung durch Nanosekundenlaser, nicht mehr nötig. Eine besonders interessante Anwendung ist das Dunkel- oder Schwarz-Markieren von eloxiertem Aluminium. In diesem Fall ist selbst unter einem Elektronenmikroskop keine Veränderung der Oberflächenstruktur feststellbar. Dennoch ist die Markierung oder Beschriftung tief schwarz, vom Betrachtungswinkel unabhängig und vollkommen abriebfest. Metalle, bzw. metallische Legierungen, die sich für dieses Verfahren eignen sind beispielsweise: Edelstähle, diverse medizinische Stähle, Kupfer, Edelmetalle wie Gold, eloxiertes oder unbehandeltes Aluminium, u.v.a.m. Die hohe Präzision der Laserbeschriftung oder Lasermarkierung auf alle Metalle und die dauerhafte Lesbarkeit innerhalb der Lebensdauer von Produkten, anspruchsvollsten Bedingungen und kritischen Einflussfaktoren ist besonders wichtig in den folgenden Bereichen: